Community Content – MS3 Basic Review

Here at BOFI we do our best to provide no-nonsense, honest advice. This means it takes a while to produce content, in an effort to include broader information this post is an impartial review provided by Tim White, a veteran of the UK MX5 hobby.

Foreword

With Motorsport Electronics’ arrival in the MX5 PnP ECU scene, they very quickly cemented themselves as the “go to” ecu of choice for the MX5 enthusiast seeking to eek more power out of their B series, be it N/A or F/I.

However, one of the “old guard” has a new Megasquirt offering which is both equally inexpensive, offers most of the same functionality, but with nearly 20 year’s worth of R&D and community support.

Enter the MSLabs Mini MS3 PnP (in 99-00 NB1 trim)

- -£78

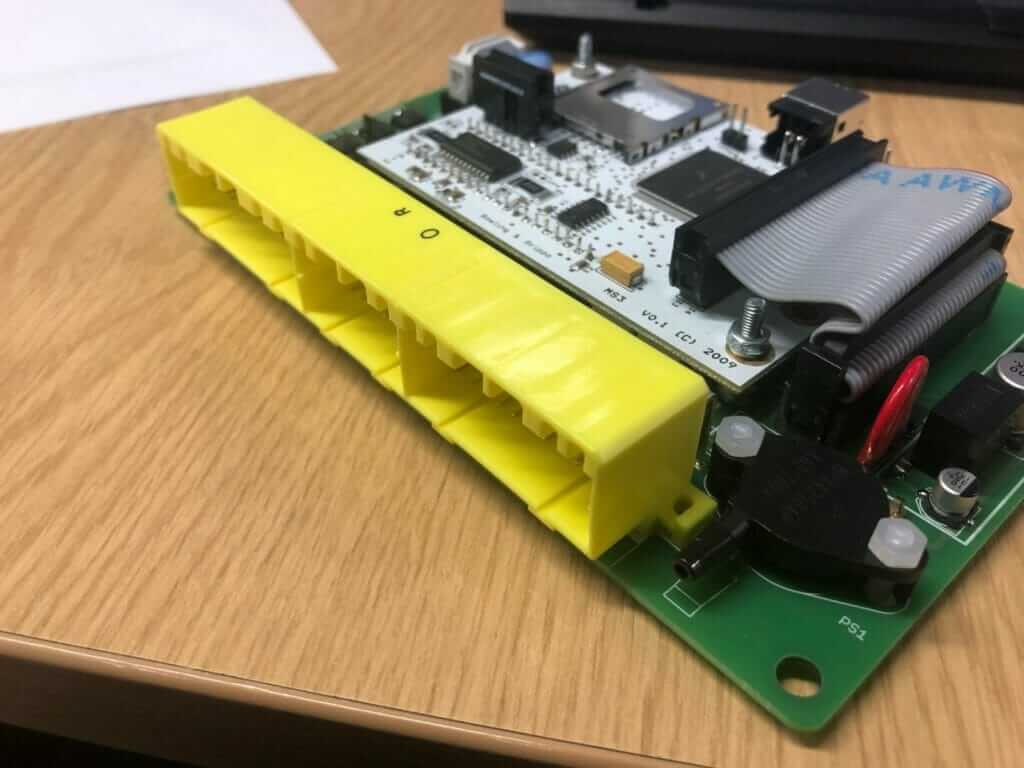

Using a genuine Bowling & Grippo MS3 daughterboard, mated to a custom PnP baseboard, this Mini MS3 allows the end user to inexpensively get on to the latest and greatest Megasquirt3 platform, and take advantage of a whole host of new features including:

- 16×16 tables for VE and Ignition

- 0.1% increments for VE, and 0.1 degree increments on Ignition table

- Integrated USB with a genuine FDTI chip (no more faffing around with adaptors)

- Full out-the-box CANbus support

- Onboard SD card slot for local datalogging

Now the keen-eyed will note, there are next to no headers for additional I/Os as opposed to the ME221 which offers an 8 pin port for such things. As this is a product that attempts to be “what you need, and little else”, multiple generic I/Os have been cut down. That said, personally I am of the opinion that you’ll struggle to find much more needed. On this particular version (99-00 NB1) the IO provided is as follows:

- 4 injector drivers for full sequential injection

- 2 coil drivers for wasted spark

- Dedicated (unsoldered) pin for VVT control/WMI/Nitrous

- EBC control via the EVAP port in the bay

- Dedicated (unsoldered) pin for Table Switching

- Dedicated (unsoldered) pin for Flex fuel sensor input

- Dedicated (unsoldered) pins for CANbus

- Integrated NB/NBFL alternator control/regulation

- Knock sensor support through OEM loom

- VICS control through OEM loom

- Vehicle speed sensor through OEM loom

- Clutch/Neutral switch through OEM loom

- Narrow/Wideband support through OEM loom

- IAT using OEM loom (NB IAT is separate to the MAF unlike NA chassis vehicles)

- 1x spare 0-5v input through MAF wiring

- Jumpers for EU/JDM/USDM options regarding clutch/neutral switch wiring, as well as oem immobiliser if present

For most users, the functionality offered in this “mini” offering, isn’t as cut down as the name nor price might imply!

Use Case

My car (affectionally known as Nudes) is a 98/99 NB1 JDM import in RS trim. Shipped with a mild exhaust cam, 6 speed trans, and a 3.9 type 2 Torsen LSD, this non-VVT 145HP 1.8L Roadster will serve as the perfect base for my lofty (or should that be forced?) aspirations. As far as “ECU affecting modifications” goes, the car has none. It has an aftermarket Cobalt backbox, and little else of note. As such, it is a clean slate.

Having previously used the ME221 on my old NA8 and been impressed with what it offered, but equally irritated by what it lacked, I was open to the prospect of jumping ship to one of the other offerings on the market. Sadly it appears Link are yet to provide an NB offering, Omex and Adaptronics have a very high entry price, and Haltech can be tricky to acquire let alone find a tuner for. That left reinvestigating Megasquirt.

My prior experience with Megasquirt had been a mixed bag. A clone ECU with minimal documentation and subsequently very little support made for a brutal learning curve that left my old NB8 without a tacho for its entire life, as well as non-existent alternator regulation or idle control functionality would of almost been enough to sour me to MS, however, past those issues, the actual core product worked very well, and critically was one of the easiest tuning platforms to get started with for one very simple reason; TunerStudio.

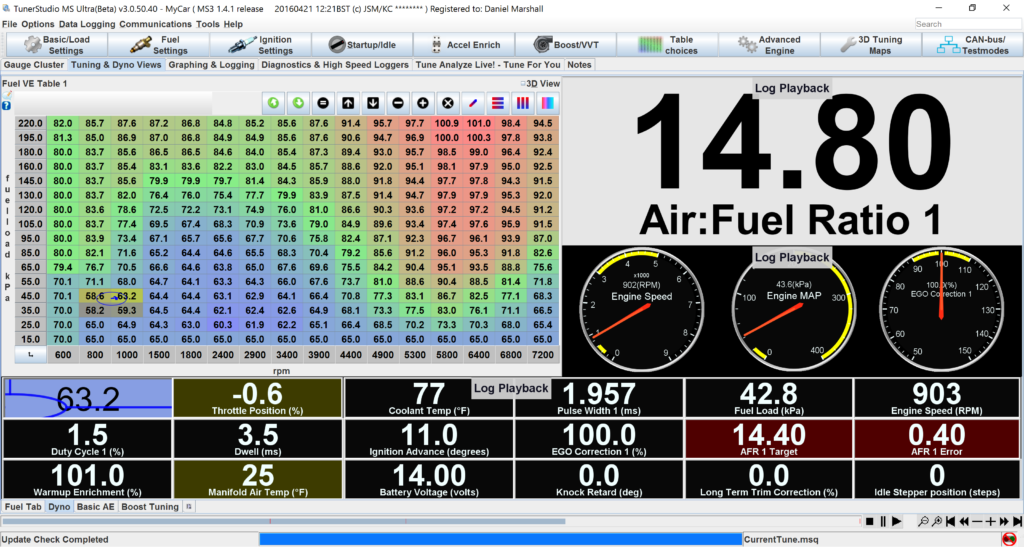

TunerStudio and MegaLogViewHD are two of the most polished and well documented ECU tuning programs on the market, and the fact that they’re the subject of hundreds of independent video and written guides makes their learning curve soft and cushy.

Deciding and placing the order

Reaching out to MSLabs/Reverant who’s long been known to make quality Megasquirt ECUs for the MX5, he informed me of his new Mini MS3 which piqued my interest very quickly. It would cover me for most eventualities I could think of (boost is planned, migrating to a forged VVT engine is certainly a possibility), at an attractive price, so without much fuss, the order was placed on the morning of the 29th of December with a tracking number and shipping confirmation following later that day. By midday on the 2nd of Jan, the unit was on my desk.

Provided with the bare-essentials, the board shipped with a quality USB cable, a test sheet showing the full range of functions of the board had been tested, and a copy of the invoice.

The Install

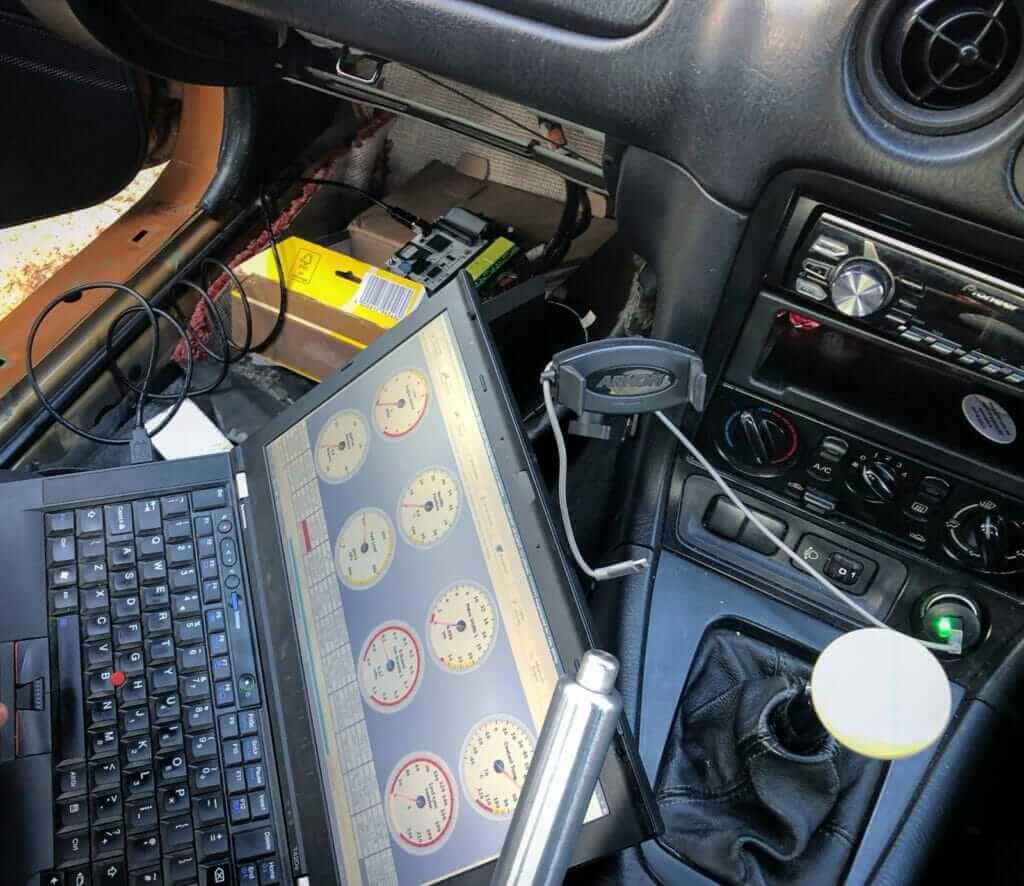

A weekend was picked, a plan was made, and I made the pilgrimage up to BOFI HQ with a box of goodies in my boot.

The installation was and is a fairly run-of-the-mill thing with most PnP ECUs, and as such, I’ll hold back on going too in depth.

Like the ME221, the Mini MS3 is designed to replace the PCB inside the the stock ECU case, so a couple holes are going to be required for USB cable and a vac line for the MAP sensor.

On the wideband front, taking a leaf out of Winston’s book, I went with the Spartan2 controller & LSU4.9 sensor.

As one of the cheapest (and no-frills) options on the market, I knew it was well known and supported, and frankly would simplify the installation. Because of the lack of a gauge and the weather-proof design of the Spartan2, the unit is perfectly suited to live in the bay. This suits my penchant for simple and neat installations well, as it allowed us to wire the unit into the plug of an old faulty OEM 4 pin narrowband, which would both provide power to the unit, and return a 0-5v signal to the MS3 over the correct wire.

With all of that done in the space of a couple hours (in our defence, it was very cold, we needed numerous tea brakes to regain some warmth, and Dan knocked up some truly epic Bacon sarnies which needed our undivided attention for a good 15 minutes or so!).

Beyond the vac line and wideband installation, n0 changes or modifications to the car are needed.

Setup & First Start

The Mini MS3 comes with a basic quickstart guide which covers how to download/install TunerStudio and the FDTI driver should you not already be familiar, as well as how to setup the base project in TunerStudio with the appropriate ECU definition he provides. This was followed without issue, and we were soon presented with TS’ default main screen.

A quick check of all the base settings confirmed that the base map provided by MSLabs had all the correct values (injector size, engine size, trigger types etc) as well as direct pin naming in plain English which certainly makes life easier.

The timing gun was fired up, 10deg static timing set, with the injectors disconnected/disabled (as a personal preference, I prefer to physically disconnect the injectors for this, even though it can be done through the ECU), and the engine cranked to read and set base timing. Again all outlined in the Quickstart guide, and for the most part par-for-the-course when installed an aftermarket ECU.

With the base timing set, a quick calibration carried out on the TPS and wideband signals (14point7 provide an excellent guide for calculating voltage offset on their website which makes super accurate AFR readings very easy), it was time to crank Nudes up and see if she caught.

Which she did. Very easily in fact! Not that it wanted to say running for more than a couple seconds though!

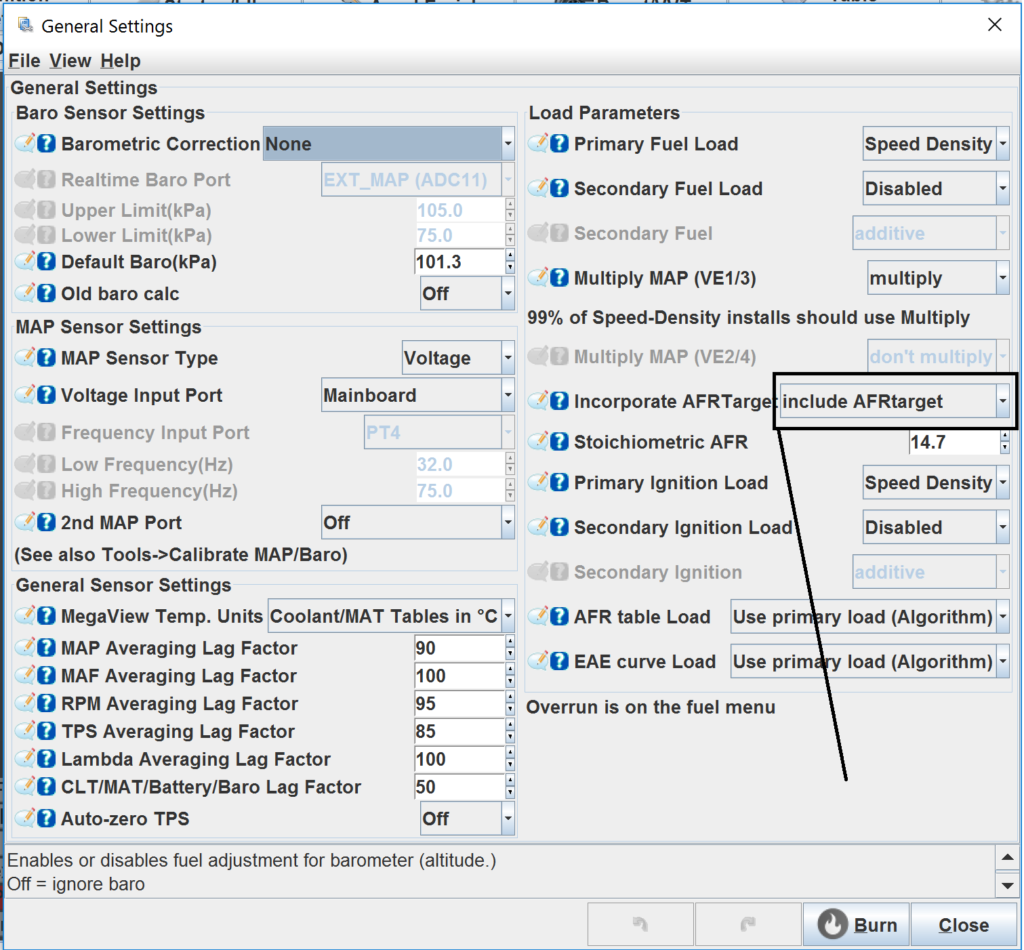

This largely boiled down to something we’d also opted to investigate in MS3; Incorporate AFRTarget

Using this mode, the AFRs are incorporated in the fuelling calculation, and as such, makes for a smoother VE table. This mode is something many tuners and MS owners on miataturbo.net suggest using when “starting out with a fresh map” as its benefits are well worthwhile. Namely; once mapped up, changing the AFR target on the AFR table will alter the calculation for fuelling, meeting the new target. No altering VE tables after setting a new AFR target!

So, Dan jump behind the keyboard, threw a little more fuel into the mix as the MSLabs base map does not enable this mode by default. And with that, she was idling quite happily around 1100rpm at a “slightly-but-not-eyewatering” 13:1 AFR.

It seems that the ICV logic is both VERY quick, and pretty damn accurate out the box, as 0 fiddling of BIS screws nor PWM values was required to have the car starting and idling from bone cold (with ambient around 5deg on that particular day) with no effort at all.

With the car starting and idling fine, trim was buttoned/bolted back up, and the car left to warmup in preparation for some road tuning.

Dan at BOFI’s Thoughts

I’d originally heard a rumour about this ECU as a market proposition when picking up my 850cc injectors for the 1.6 turbo build about 8 months ago. So when Tim announced he was taking the plunge I was more than interested in getting involved.

It all managed to fit together nicely as I’d been pestering Tim to take out the turbo 1.6 to see how a well sorted car feels, which hopefully would help him to finalize the plans for his car.

The ECU is a similar configuration to the ME221, in that it fits in the stock case with a little modification for the USB cable and the Vaccum (boost) line. As with all MS Labs made ECUs it’s a quality piece of kit, well put together and well thought out.

The install was as simple as any PNP with the hardest part being deciding a clean place to ground the wideband heater, which took all of 5 minutes.

Tim did decide to change things up a bit with the implementation of a different setting, include AFR targets, which meant that he car didn’t start and idle without a couple points added to the ve table, but once it did, with the timing checked, it managed a smooth and stable closed loop idle without further fettling.

The next steps are the usual road tune processes, changing the timing table to a proven safe NA map, changing the VE and AFR targets to suit and working in accel enrichment and dialling in overrun fuel cut.

All told after a couple hours of driving there was little left to do to improve it, without a dyno to hand at least. Stopping back on the driveway the car sat and idled at 850rpm +/- 15rpm with an afr of 14.5 – that AFR sat solid and unchanging for over 5 minutes of idling and that’s with the MS set with zero smoothing of the AFR signal, it’s great using the new TS Ultra with its support for custom layouts.

Impressive to say the least, and unless you knew, you’d assume it was a particularly peppy stock car.

With a personal preference for Tuner Studio, this option is a great choice for anyone looking for a PNP solution. With that being said, if your tuner has a preference for ME221, there really is no reason to fight them on that – it’s still a great ECU with excellent UK support and a growing user / fanbase as this picture more than proves, the MS perhaps suits the tweaker a little more.

Living with an MS3 as the proverbial fiddler

So since Dan’s hard work putting together a STRONG and smooth map on Nudes, I’ve been using the car in its usual every-day-duties with no problems to speak of.

On the drive south from Bofi HQ, autotune was left running in “hard” mode to smooth out any little rough spots that we may of missed during a couple hours of street tuning, but few changes were recorded!

Cold and Warm idle are stronger and smoother than ever. The car reacts quickly and without issue to load such as the heater or lights being powered up, and has been consistent with starting in cold or mild weather.

Power is smooth and progressive through the entire range, with a strong torque surge north of 3.5k or so.

But I can’t leave well enough alone, and like to fiddle. So I had a few things I wanted to play with, and some features I wanted to enable and test out.

VSS Input

During Nudes’ import process, the car was badly converted to MPH using a sticker and signal convertor. It also had the JDM 112mph speed limiter “disabled” which actually involves chopping the wire that goes from the clocks back to the ECU reporting speed.

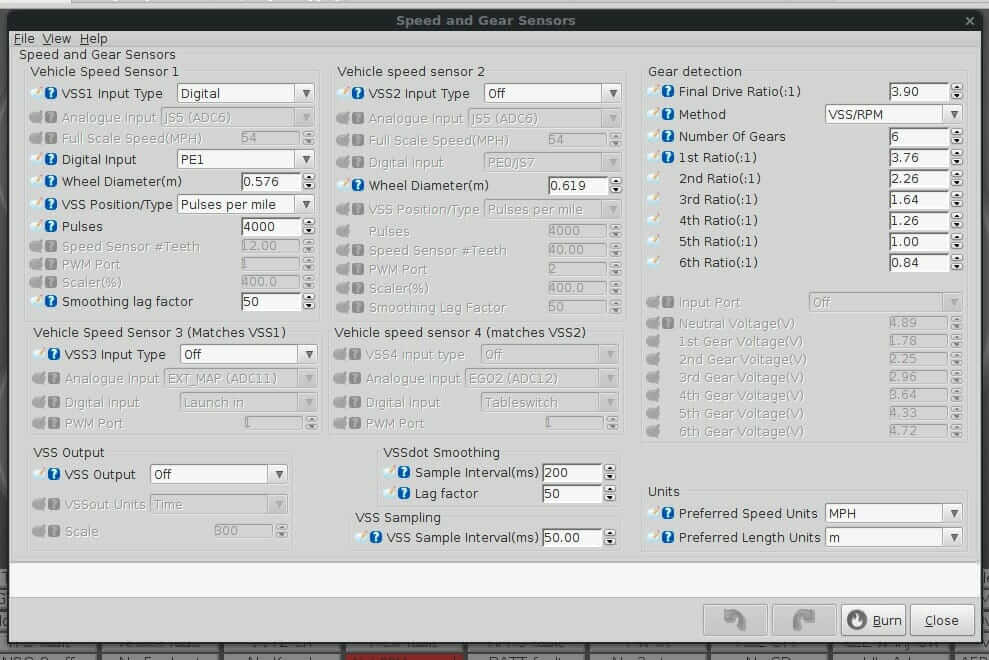

Whilst I had removed the convertor and fitted new foils a while back, I hadn’t repaired the wire for the speed-signal, so this needed to be addressed. Once sorted, a quick jump into the “Speed and Gear Sensors” menu in Tuner Studio was required to pop in the appropriate settings

MS has support for gear detection which I also took a moment to enable and configure with my gearing and trans ratios.

With that set, more data is now available to me during datalogging, as well as the possibility for a digital dash implementation. Oh, and better launch control & flat shift…

Launch Control & Flat Shift

As a 30 year old child, I obviously wanted launch control, as well as flat shift. As the ECU promised this support out the box, this was a no-brainer for me to enable and setup.

A couple emails back and forth to MSLabs allowed me to establish the correct jumper position on the board (my JDM car is wired with the clutch and neutral switch in parallel, and only actually ground out when the engine is running which made for some fun in trying to establish whether I had a setting/jumper wrong, or a fault in the circuit somewhere).

Once established that my testing methodology was essentially flawed, and the jumper set to the correct position, the indicator light in TunerStudio sprang to life during clutch and shifting operations.

I won’t tell you I’ve got it setup perfectly yet as that would be a lie. Because of the VSS support, I can really fine tune when and how launch control operates, as well as how and when flat-shift operates. This will take some fiddling on my part, however, there’s hundreds of pages of community posts about it, so I’m sure I’ll find a setup that works!

But for now, I can make childish yobbish popping and banging at a standstill with my foot on the clutch pedal; a good enough starting point for this particular child!

Internal Datalogging

Internal datalogging support is something I very much liked the idea of, and was part of what drew me to this particular ECU. As it stands on the Mini, this functionality is good, but if I’m honest, could be better.

One of the big differences over the MSLabs Basic MS3 and this Mini MS3 is the lack of a Real Time Clock on the board. For 90% of usage, this is of no consequence. Unless you want to datalog. Instead of neatly timed/dated logfiles, they’re sequentially named.

Now, this isn’t the end of the world at all. But it does make it a little trickier if you log ALL THE DAMN TIME like I do. Personally I’d of happily paid a few quid more if this could have been implemented natively.

Pulling logs via TunerStudio is simple enough, can be read easily in MegaLogViewHD, and the data used to tweak things with VEAnalyzer if needs be. No complaints there.

And at least with a replaceable SD card, it’s of no great consequence if I wear the card out as I can replace it for less than the cost of a cup of coffee.

That said, I can add an RTC via CANbus, so that’ll make for an interesting little side project down the line perhaps?

Final thoughts, and comparisons to the ME221

Summarising has never been a strong point of mine. This review is a great example if I’m honest. I figured it’d be a couple pages worth, but I’m 5 pages into writing this and still have a fair bit to expand on!

So let’s start with a cliché pros-vs-cons list

Pro

- Price

- The Mini MS3 sits in the same sort of price bracket as the ME221 and the Link G4+ – This will vary from supplier to supplier, as well as version

- Functionality & Expandability

- Whether your aspirations are of the natural, turbo, or supercharged nature, it’ll cope quite happily.

- It’ll drive all the OEM hardware and features without complication or modification

- Native CANbus is a big plus and in my opinion balances out the lack of spare general IOs

- Community Support

- No getting away from it, 20 years’ worth of forums, tuner experience, and support goes a VERY long way if you’re prepared to work a little for answer and help. And if you’re not, there are Megasquirt specialists all over the planet who you can pay for support/modifications/assistance.

- Setup

- Personal perspective here; this was as easy to get running as an ME221 which is very much touted as being the easiest.

- Software

- This is the big one in my opinion. TunerStudio and MegaLogView are phenomenally powerful, are easy to use, and theres more documentation out there for them than you can shake a stick at, and are multi-platform. Mac or Linux user? You’re good to go!

- Mobile apps that range from basic dashboards through to full tuning suites that can be run on phones or tablets

Cons

- Support

- Whilst community support is top notch, and the manufacturer is fairly quick to respond to emails what seems like 7 days a week, there’s no getting away from the fact you’re dealing with a product that’s produced in a different country, with your main point of contact also being in a different country, BOFI’s support aside.

- Functionality & Expandability

- Whilst it’ll do what I need it do, and most of what I want it do, there are still some holes, and I cannot argue that it has LESS IOs overall than other market offerings. CANbus is awesome, but it will require more cost to add sensors to in the long run.

- I’d of really liked to of seen a RealTimeClock included as it would of really made the internal datalogging that much more useful.

Personally, I’m very happy with my choice. The long-run benefits outweigh the negatives, and give me a suite of applications I find much better to work with overall.

One of the long-standing issues with MS was always long lead times, or high cost from having one built by a UK tuner. This no longer appears to be the case, as lead time was short, and pricing was very much in keeping with UK offerings from other ECU manufacturers.

Hardware support has been faultless from MSLabs, and some of the stuff I’ve fiddled with that’s out of scope for the manufacturer/vendor has been easily figured out/advised upon by the community as a whole.

Installation process was very much in keeping with the ease of the ME221.

Appendix/Notes for comparison

TS > Meite

– Re binning tables

– VEAL (main VE tables + Warmup Enrichment tables)> Autotune (VE table only)

– Performance is great on a wide variety of machines with gauges, logs and more – MEITE requires a reasonable machine.

– Platform support (Windows only vs Win/Lin/OSX/Mobile)

– Full CAN support

– Theme support for gauges/displays

– UX far simpler, easy to jump between windows/setting panes

Mini MS3 > ME221

– Integrated USB

– Full CANbus support on dedicated pins

– Larger user base with independent experience and knowledge (not tied to one vendor/supplier)

– Single contact point for support leads to longer periods between asking a question and getting a response

– Open source nature means better support for 3rd party products (i.e. canbus breakout board for more sensor inputs)

– BASIC dashboard app (was £11, now appears to be free) for ME vs full tuning suite for tablets/phones (MSDROID)

– Integrated SD datalogging

*It is always recommended to seek professional advice when selecting an ECU, if you are working with a Tuner for your build our recommendation is to go with their preferred platform to get the best out of your build. It is possible to damage your engine with a poor tune, ensure you seek advice before pushing the limits of your engine.