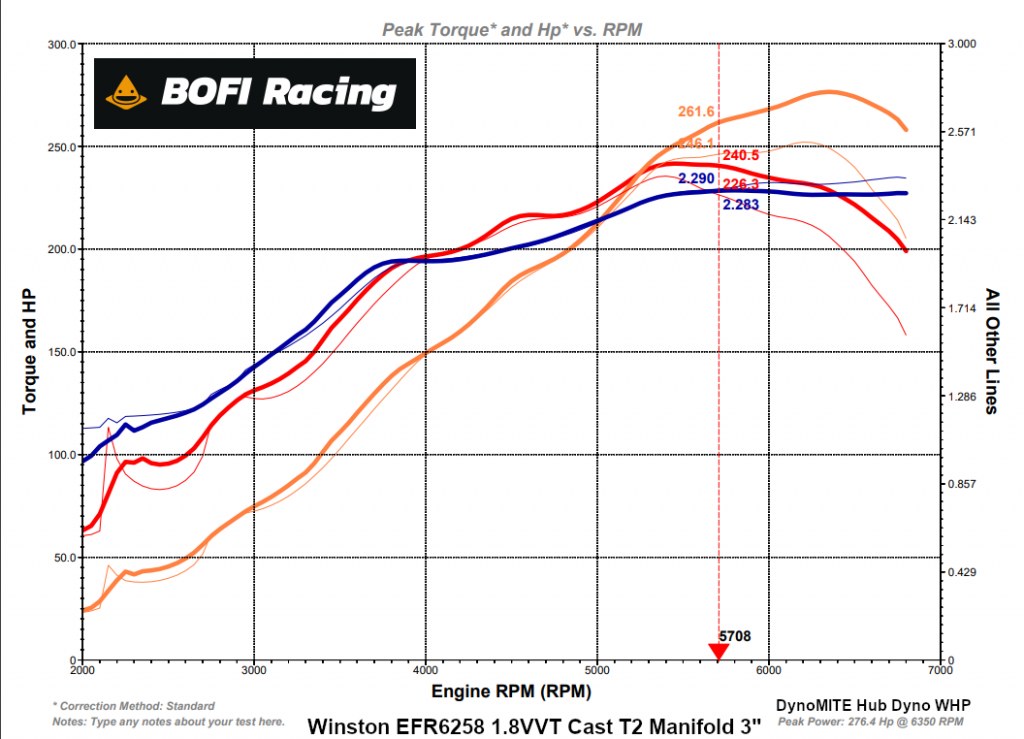

Here’s the dyno chart from this Saturday 08/06/2019 for Winston – Our 1.8VVT Rod Block. It’s been fully blueprinted and has had about 15k miles put on it since being built – daily driven, tracked etc. It was completely torn down, cleaned, honed and balanced. Using stock pistons with new rings, balanced with a Dremel.

MaxPeedingRods are the connecting rod of choice, using a mixture of ACL Race mains and King Racing Connecting Rod bearings. It has a stock VVT oil pump that has been shimmed to provide ~70PSI of oil pressure. It has had a slight skim bringing the compression up from 10:1 to 10.25:1. Our previous dyno attempts were stopped around 5,5k, due to spark breakup on the stock coils. It runs on VPower and only VPower, using BKR7E plugs.

In this run we managed to pick up the best part of 30WHP at the very top – that was done by adding as much timing as we could get away with. With each point being worth the best part of 10WHP, it was clearly desperate for it. With the stock pistons, one serious knock event at that high in the rev range would likely have been fatal to the engine.

You can see from the blue line that we have boost creep issues, to the point where we simply couldn’t control it. the turbo is an EFR6258 running a 14psi spring Turbosmart Twin port – the part number specifically for the EFR. In theory, with zero boost control – which is what this run is, we should be sitting around 14-16PSI. So why are we up at 21PSI on the first run and 18.5 on the last?

Timing. As we added timing up top which netted huge horsepower gains we can see the boost has dropped, airflow through the engine has increased. In order to add that timing, we’re having to run far richer than we would want which causes other issues. It’s the same story below 5000 RPM, an area we simply couldn’t touch without finding knock.

It’s certainly a reasonable curve, nice and linear and its a ‘300BHP’ car – but we should be reigning this in, it should be 300WHP all day long hitting 240ftlbs at 4500RPM or less and holding that flat to 7000rpm. That’s it for this setup, the only other change we’re considering is moving to an 8 step colder plug on resistorless plugs – but the fact of the matter is, now we’re running LS coils it has enough spark to blast through the stupidly rich AFR we need to stop it from detonating in order to run the timing to stop it from hitting boost cut at 250KPA.

The next time we update you will be on a low mount, we see this as a flow issue. These peak numbers aren’t dissimilar to what’s been achieved on T2 cast manifolds prior and anyone putting down bigger numbers seems to be running E85 – negating the knock issue.

A couple of notes here;

Yes, it’d have less knock and we could achieve a higher peak with 8.6:1 compression pistons – at the tradeoff of response. When this engine was built the original plan was an MP62 supercharger, it was also an absolute riot naturally aspirated. This car has had so many development hours in it, we’re quite confident this is a safe number, knock detection used is the Phormula Knock Analyser Pro (det cans). Could we push it further? Not below 5k, it won’t take any more without detonation.

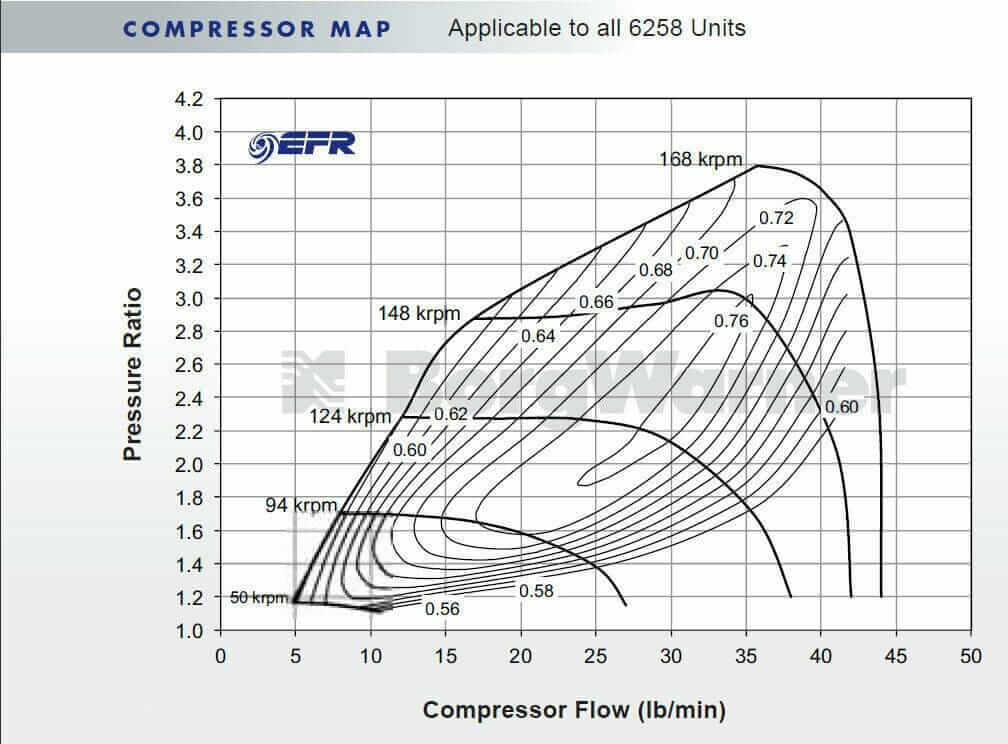

We’ve considered the rod length of the wastegate actuator but as it’s a set part number installed correctly we don’t believe the over-boosting is a wastegate issue – more an issue with how efficient the EFR is with exhaust considering how much difference it makes when turning up the timing and how far out we are from where we want to be.

Considering the boost pressure we’re at and the airflow of the engine to make that power we have to assume we’re smack in the middle of the compressor map – barely taxing the turbo at all and just throwing un-used combustion at it generating over-boost. From this, it’d seem we’re around 30lb/min and PR of 2.3 right in the most efficient island.

2 comments

[…] for our friend Daniel Marshall share this parts test review for our H-Beam connecting […]

Whats the turbine housing A/R?

If it’s the smaller 0.64 A/R I would consider changing to the larger 0.85 A/R.