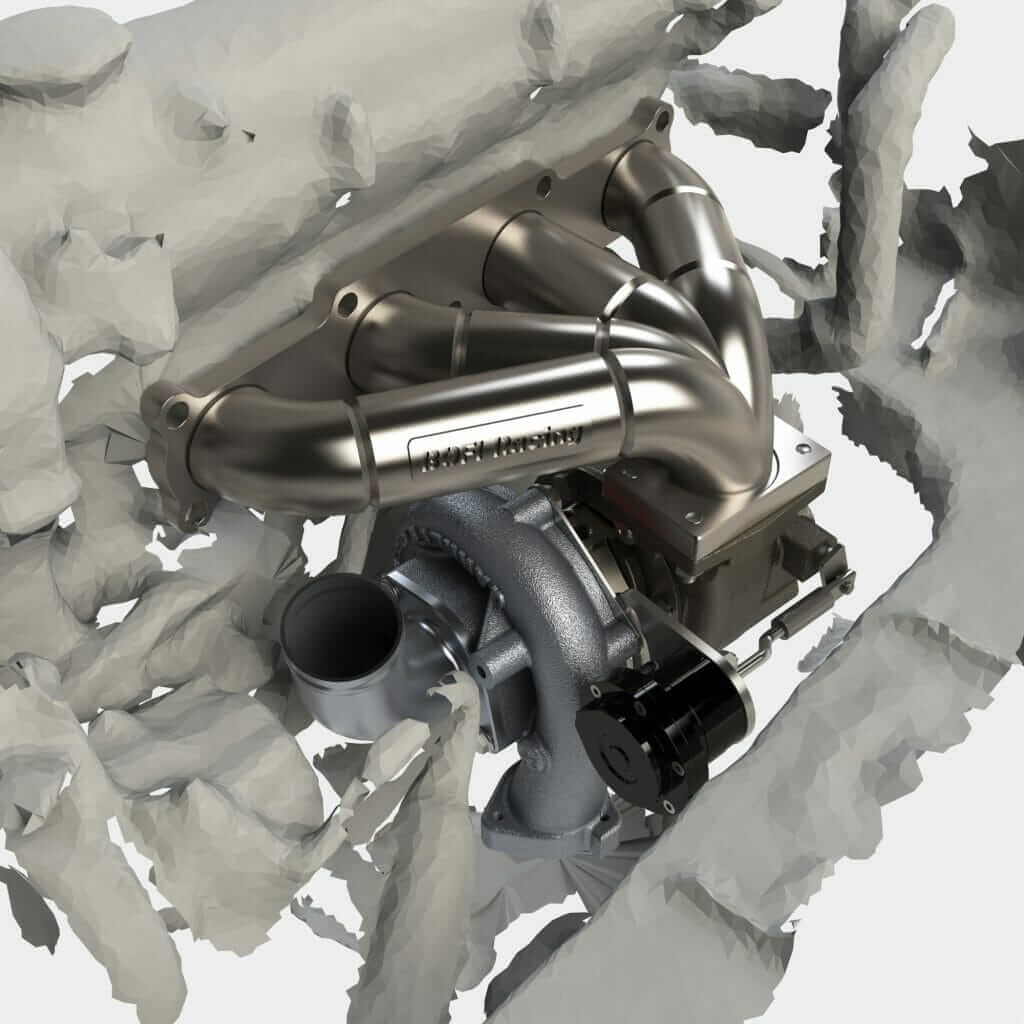

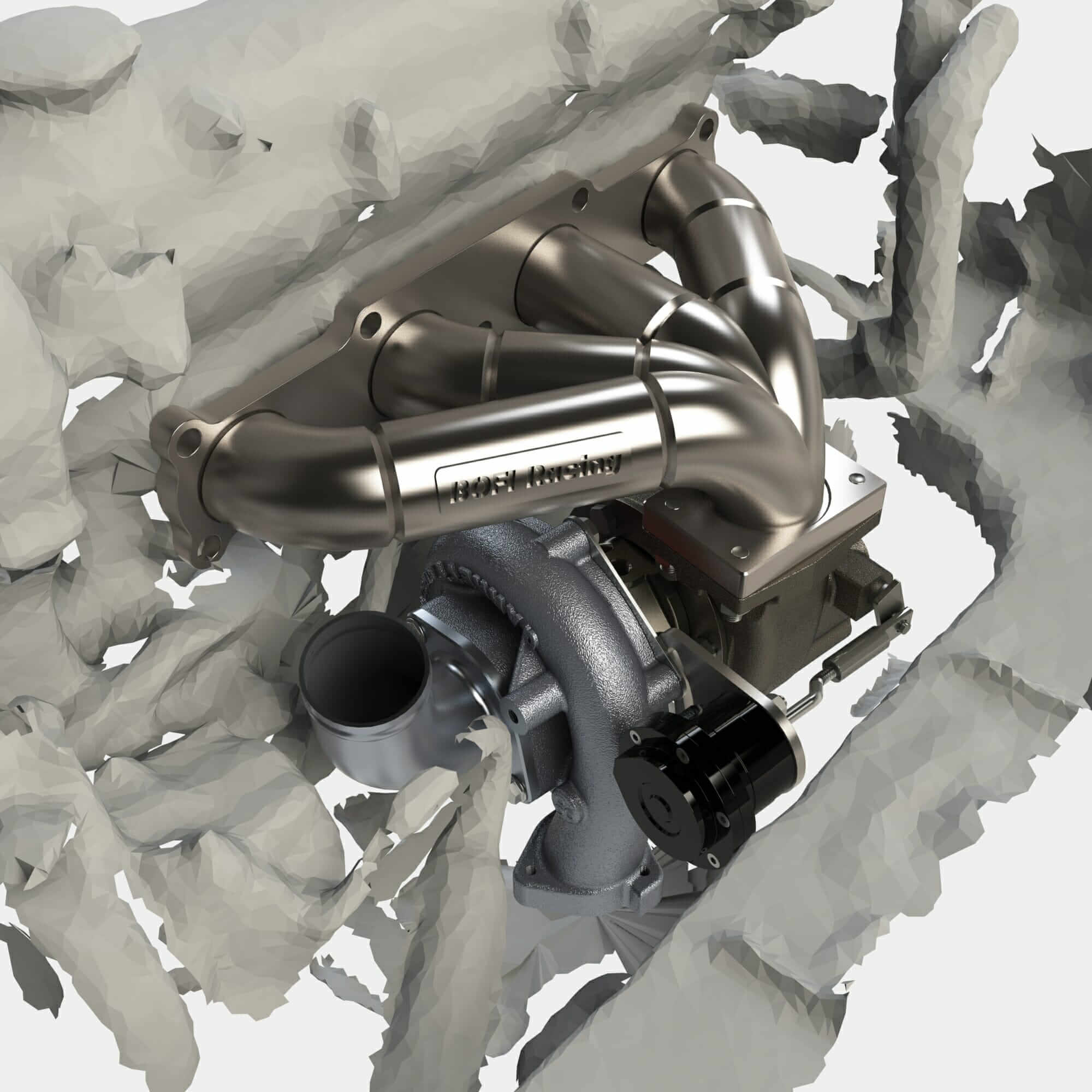

BOFI Racing T2 Low Mount Turbo Manifold

What does it mean to ‘turbo your mx5’ or any car for that matter? Does it mean bolting a cheap unresponsive turbo to a cheaply manufactured manifold and chasing cracking and faults?

Does it mean making compromises to the build of the car, like notching the frame rails, removing air conditioning, not being compatible with power steering? All in an effort to achieve positive pressure on your boost gauge.

Is it about flutter and BOV noises? Is it about bonnet vent downpipes?

Does it mean slapping a big ol’ T4 Garrett on the car and holding on for dear life as it spools?

Here at BOFI – what it means to us is power, response and reliability. The holy trinity of the equation, with us it’s possible to pick all 3, not just 2.

We set out to build more than just a turbo manifold or turbo kit, we’re building a solution to go faster than the competition and we want to take you along that ride with us.

Goals

We have the following goals for the project, all of which are achievable based on the work completed so far with engine bay scanning and cad design work. It is being designed as a platform that will work with your smallest T25 all the way up to an EFR 7163.

- Left Hand Drive Compatible

- Right Hand Drive Compatible

- 1.8 & 1.6 Compatible

- T2 Flange

- 3” Downpipe

- Minimal Downpipe Bends

- Power Steering Compatible

- Air Conditioning Compatible (Not the EFR Series)

- Non Restrictive Intake

- Near Equal Length

- Zero Restriction

- Strong, Reliable – No Cracking!

- Far away from the front left Brake Pipe

- T2 GT2554R to EFR7163 Compatibility

- Internal Wastegate Compatible

- Support most 2.5”+ cat back exhausts

- No cutting of frame rails or permanent modification to the chassis.

- Individual EGT Monitoring*

- Back Pressure Monitoring*

- External Wastegate*

*Are supported by the platform but are subject to additional costs and are made to order.

Project Brief

So, how are we going to make this all possible? Firstly, it’s not just us working on this project – we’re bringing in our friends and metallurgical magicians over at DaveFab for the design and manufacturing process.

They’ve had amazing success with their long tube manifold for the builders pushing insane numbers, without any cracking round lap after lap of the Nurburgring and countless track days in the UK.

We approached them explaining what we wanted to achieve and they jumped on the idea. Their long tube manifold doesn’t come with a downpipe and is a costly piece – what we’re looking to do is provide that level of power with a compact and well-priced package.

As with everything we do, we want the first units to be as good as the last and while we certainly could just ‘knock this together’ that isn’t how we roll. This is a product that’ll be around for a very long time and as such we’re designing a complex set of JIGs such that mean we can always make these manifolds and downpipes and they’ll be the same, every time.

Design Process

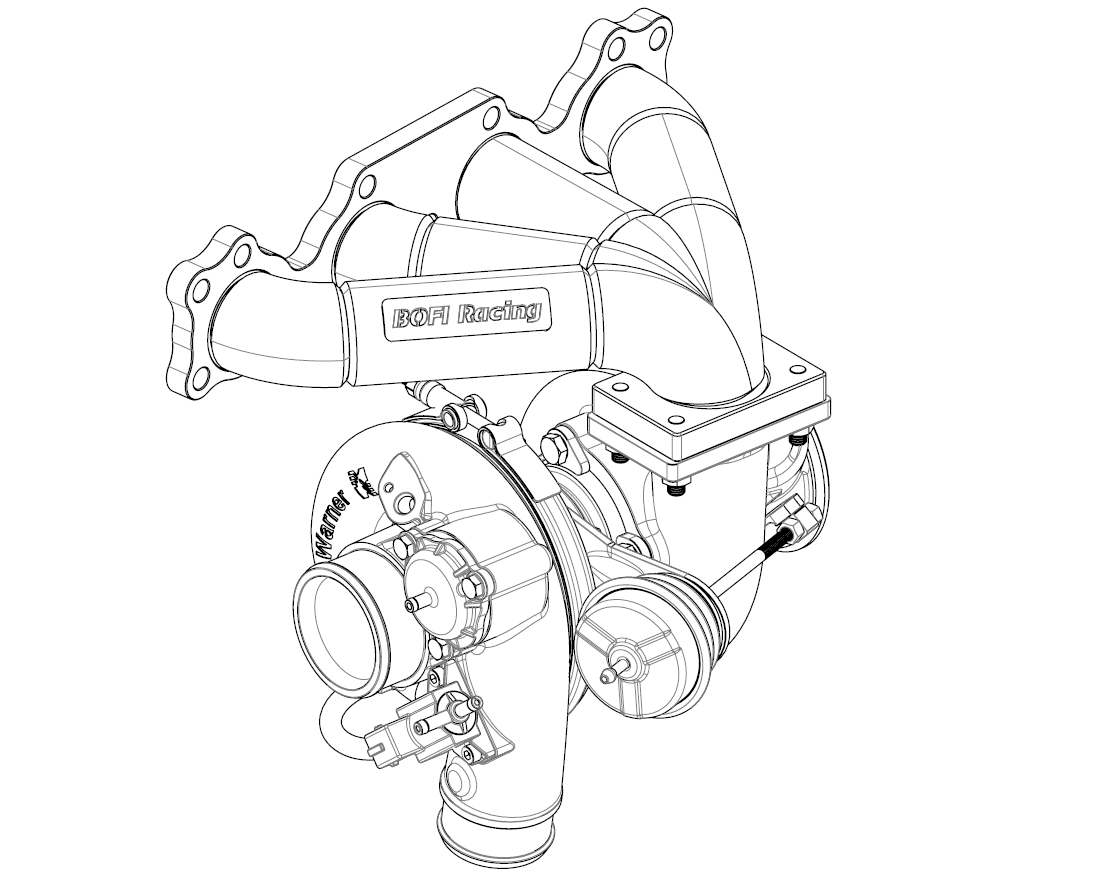

Having many cars at our disposal allows us to test each combination with ease, with that being said we’re using the latest in engine bay scanning tech as well as 3D printing processes to ensure perfect fitment before any welding takes place.

The design has been checked both in the car as well as on both 1.6 and 1.8 engines with A/C and PAS attached, considering the downpipe exit position too.

These units have been painstakingly designed to meet all the design criteria above, the only thing impossible about the brief was fitting Aircon with the EFR – but you can have everything else, power steering and left-hand drive.

It’s also possible to fit up to a GTX2871R with Air Conditioning – that’s a 550hp capable turbo! You’ll be overtaking everyone in arctic comfort in the heat of summer.

We’re also paying close attention to the air inlet, intercooler outlet, water inlet, power steering feed and position of the turbo within 3d space relative to the engine and its ancillaries using engine scanning technology and real-world testing lets us be confident in the design.

Material Selection

The team at DaveFab has experience welding pretty much anything that’ll stick together, from medical use titanium that has to be welded in an argon bubble to MSA spec roll bars for race use that is designed to keep racers alive in the event of a crash and of course, their own manifolds and product range.

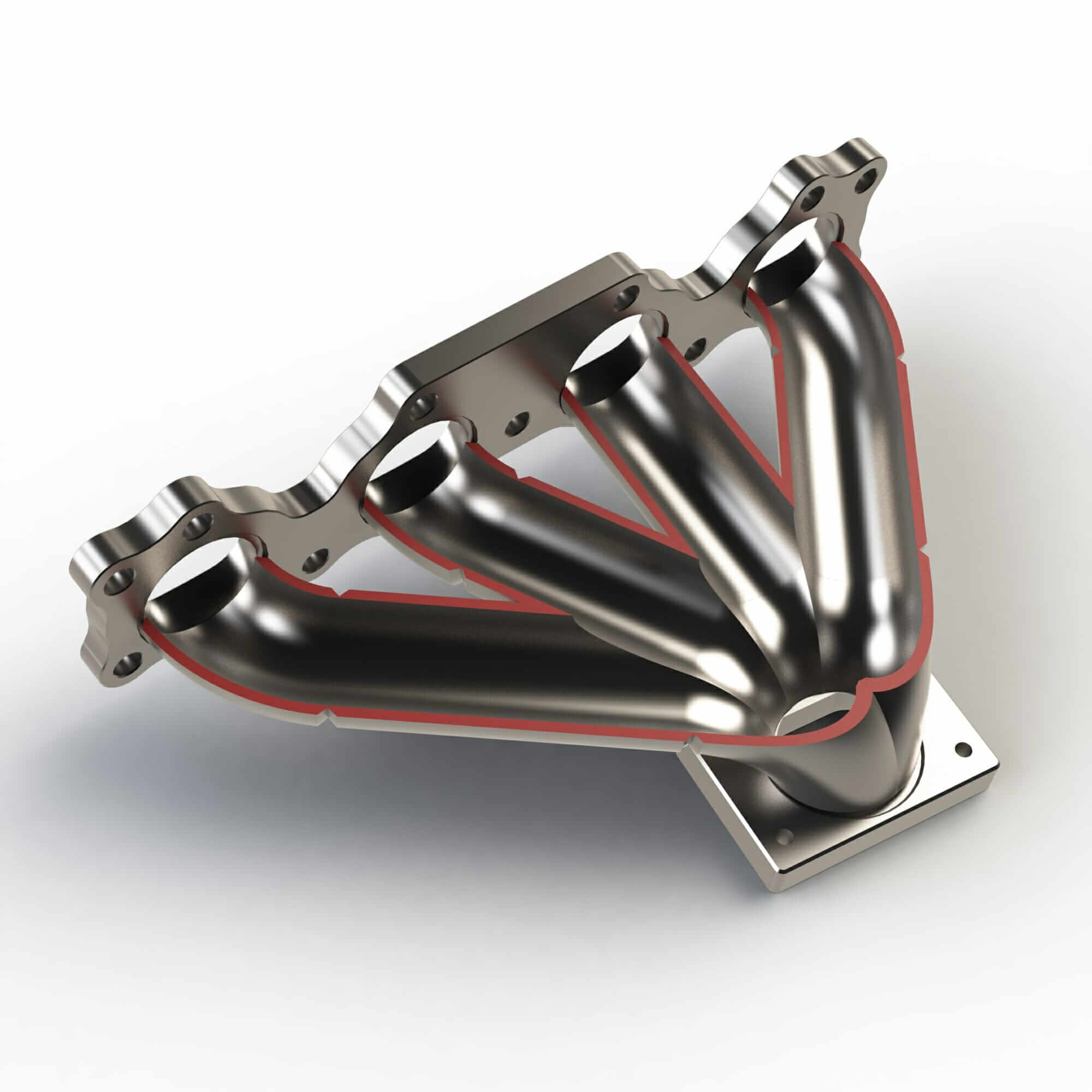

The materials have been tried and tested and will be 304L stainless for the tubing and runners and mild steel for the flange. Mild steel doesn’t warp as stainless does so it’ll remain flat for years to come and 304L stainless provides heat protection up to 1700f, considerably higher than most turbo turbine housings are rated to – Ni-Resist is rated to 1400f for example.

Typical EGTs on a turbo car should not exceed 1600f and should be between 1300 and 1500f in most situations.

When we talk about heat protection, above this point the metal starts to precipitate out the other metals that give it its strength, flexibility and other factors. At this point, the metal begins to brittle, which is one of the reasons many lower quality manifolds crack over time.

All assemblies will be fully back purged with deep bevels to ensure maximum penetration and strength.

Each flange is CNC milled to produce the most immediate and natural progression from the oval port of the head to the round port of the tubing. In the case of the turbine inlet, this is also ported to accept the perfect circle the collector becomes and converts this to a T2 Rectangle flange.

The beauty of working with DaveFab is the design and manufacturing processes that have gone into their tubular manifold have all trickled down into our project. Having demonstrated it can survive over 5,000 road miles, 40 consecutive laps of the Nurburgring and 4 track days without the slightest hint of warping or cracking, all without any bracing on the manifold itself.

We can safely say the material and design will be guaranteed to put up with any abuse you can throw at it, just as we would want it for our own cars.

Manufacturing Process

The design and position of the manifolds have been finalised and has been designed in SolidWorks with the cutting tools and jigs in mind. There is a total of 46 separate assemblies that are required to make the individual cuts and bevels for each piece of the puzzle that makes up this manifold.

These will be units that are kept on the shelf but the option of having individual EGTs, external wastegate port and back pressure ports will be incorporated into the JIG itself.

The downpipes will all be standardized, only available in 3” and will finish in a 3” VBand, they are designed to connect to what we’re calling a ‘Link Pipe’ which can either be a De Cat or a high-flow sports cat* – that’ll be 3” and mate to a 2 bolt flange that will finish at the standard cat back exhaust location – ensuring maximum compatibility and flow.

An O2 sensor bung will be included within the downpipe for use with a Bosch 4.9 LSU Wideband O2 sensor, this will be at the proper 36” of distance from the turbine and will use a turned bung for maximum longevity and accuracy.

An EGT bung will be welded on to the downpipe close to the turbine outlet, to give a true average picture of the health of the engine, this will be a ⅛” NPT boss and will be supplied with a bung.

How can we make this happen?

R&D takes both time and considerable capital investment to make happen, now this is a product that we believe for both our own builds as well as anyone looking to make good power reliably for a long time, with room to grow.

Our view is that anyone who has gone to the trouble of putting together a forged engine will want the best performing manifold they can possibly get, otherwise you may find yourself prematurely knock limited.

The thing is, you also don’t want to have to break the bank to get something quality in your hands.

It’s not possible to install EGT bungs on a cast manifold without potentially causing cracking or other issues, so individual cylinder tuning is out of the question with those types of units. Cast Manifolds also always will require a level of compromise in their design, it may be the length of the runners aren’t equal for example, or the weight of the unit is unwieldy.

We’re looking for individuals who want uncompromised power and reliability with their build if you’ve already bought into or are looking to buy into the T2 platform – you’ll want to hold out for this.

We’ve invested considerable time and funds into finalising the design of the manifold, downpipes and ancillary products and at this point, everything is ready for us to hit the button on the manufacture of the JIGS and the kits themselves.

Project Timeline

Pre Order begins from 23/03/2019 and the first delivery will be late 2019, with all pre-order units being fulfilled on this date or before, there is potential to bring this date forward the faster the slots sell out.

So, what do you get for putting your faith in the project? We’re planning on making loads of these manifolds every year, but yours will be the only one marked with ‘Launch Edition’.

There will only be 25 of these Certified Launch Edition Kits. That’s it.

As a thank you for being part of the Launch Crew, you’ll receive a number of benefits and items with your purchase.

- A Numbered Certificate of Origin (Signed, Frameable)

- A Launch Crew Long Sleeve (Arms Covered on track!) with the manifold design on the back

- A High-Quality Resin Scale 3D Manifold Keychain

- A Launch Edition Bottle opener (for after the track)

After that, the manifolds will be sold at their RRP.

As part of the Launch Crew, you’ll also be invited to a Whatsapp / Messenger / Facebook Group where we’ll share regular updates on the production process and in 2020, we’ll look at organising a track day or some other type of meet up where possible.

Be part of the Launch Crew and get your kit secured today;